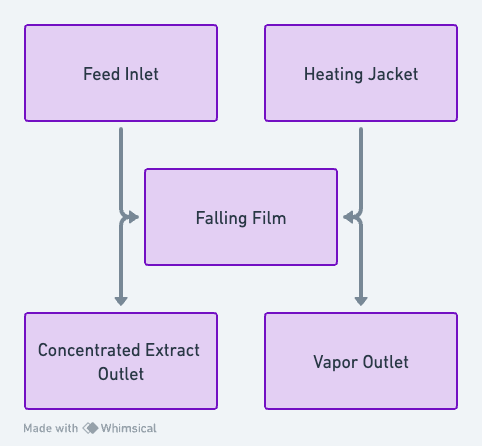

Falling Film Evaporation Process: From Feed Inlet to Concentrated Extract

This diagram illustrates the intricacies of a falling film evaporation process, highlighting the key components and flow directions. It starts by showing the “Feed Inlet Film” where the initial liquid feed is introduced. As this feed travels downward due to gravity, it forms a thin “Falling Film” on the heated surface of the evaporator. Concurrently, a “Heating Jacket” supplies controlled heat to the falling film, initiating the evaporation process.

Two outlets are featured in the diagram: one for “Concentrated Extract” and another for “Vapor Outlet.” The concentrated extract is the remaining liquid after the evaporation process, collected for further use or processing. The vapor outlet serves as the exit point for the evaporated component, typically recovered or treated for other applications.

This falling film evaporation process is highly relevant in industries ranging from food and beverage to pharmaceuticals and petrochemicals. Its efficiency in concentrating solutions and separating volatile from non-volatile components makes it invaluable for producing high-quality extracts and for resource recovery.

📗 Note: If this diagram is the match, then the book is the bonfire. Spark up your knowledge by clicking here 📗.